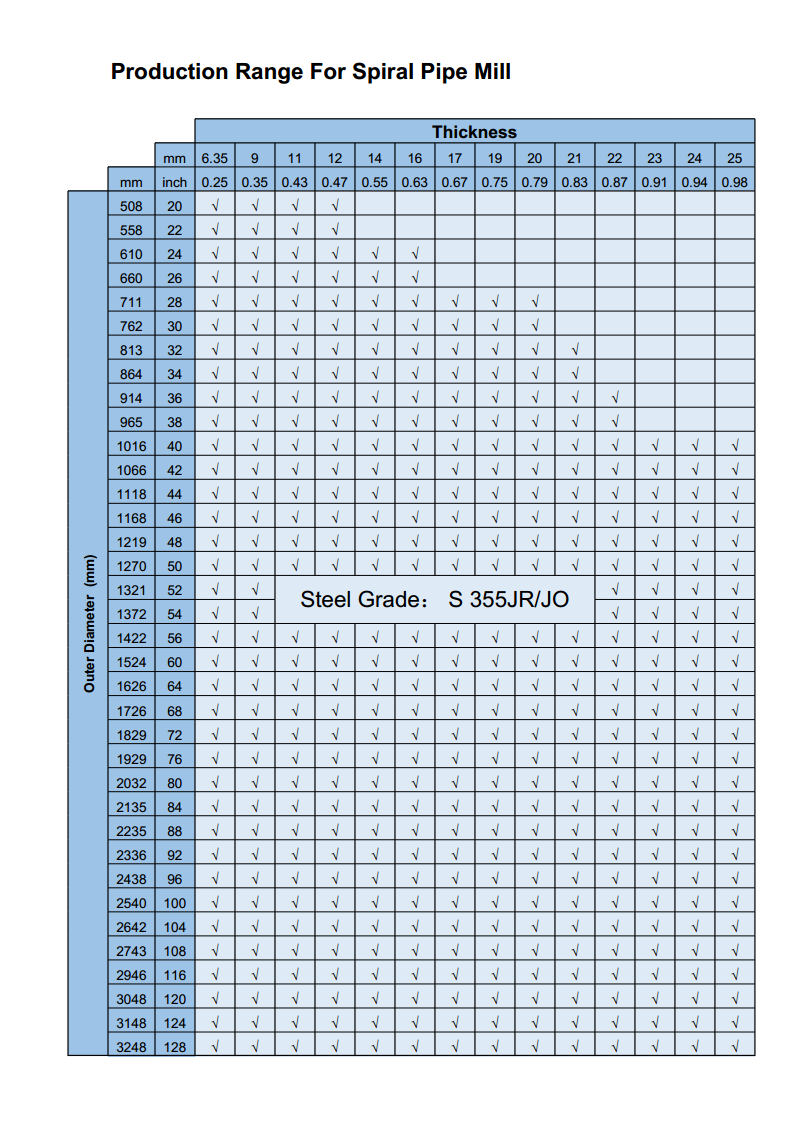

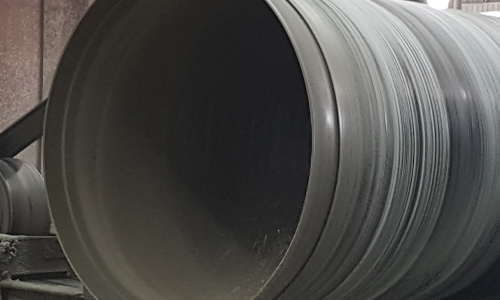

With the addition of a new large and state-of-the-art Spiral Pipe Mill in the year 2013, Able Steel Pipes is capable of manufacturing spiral welded steel pipes up to 3100mm Diameter x 25mm thick.

The methods of manufacture used in our factories are:

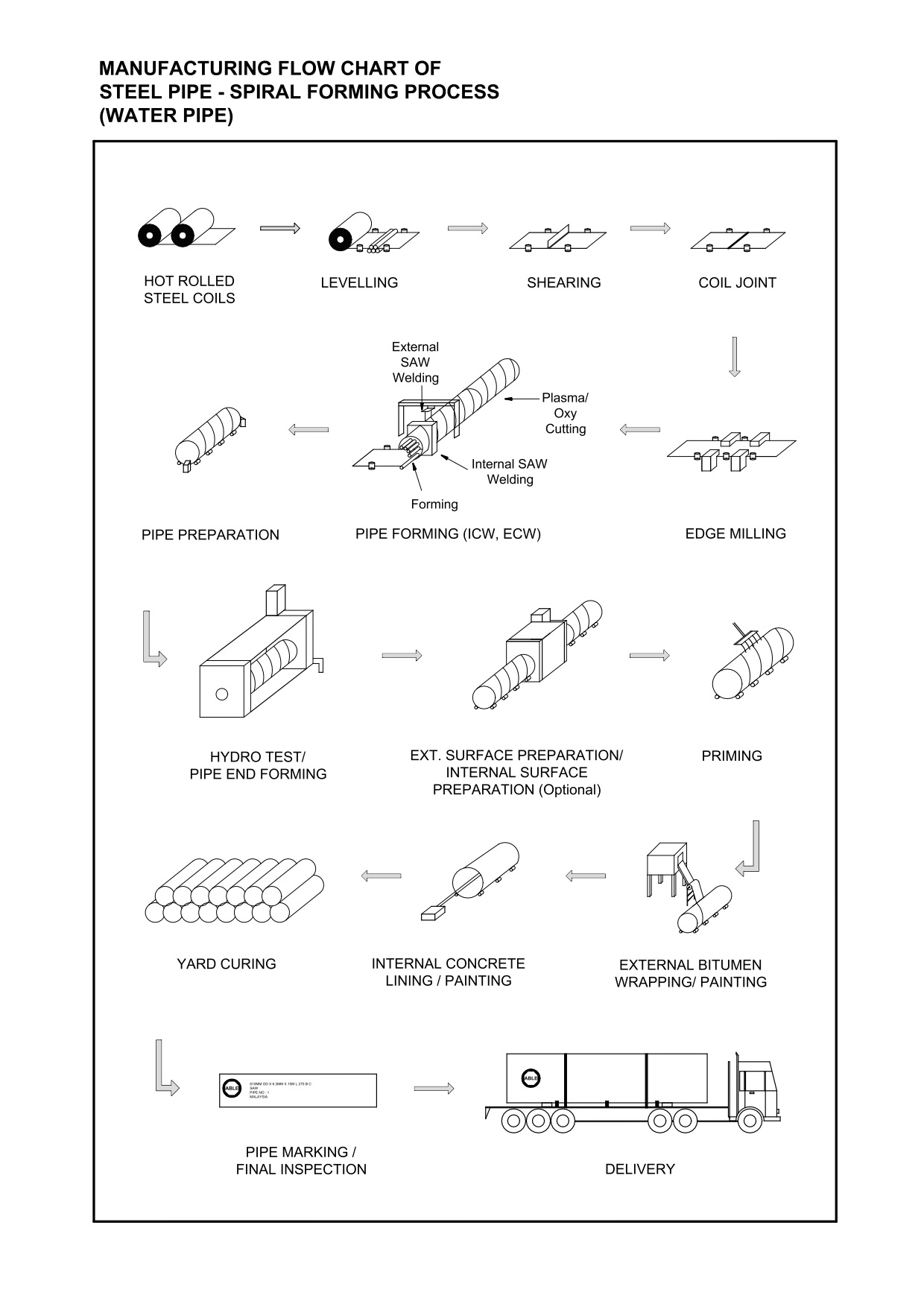

- The Spiral Forming Process (Water Pipe)

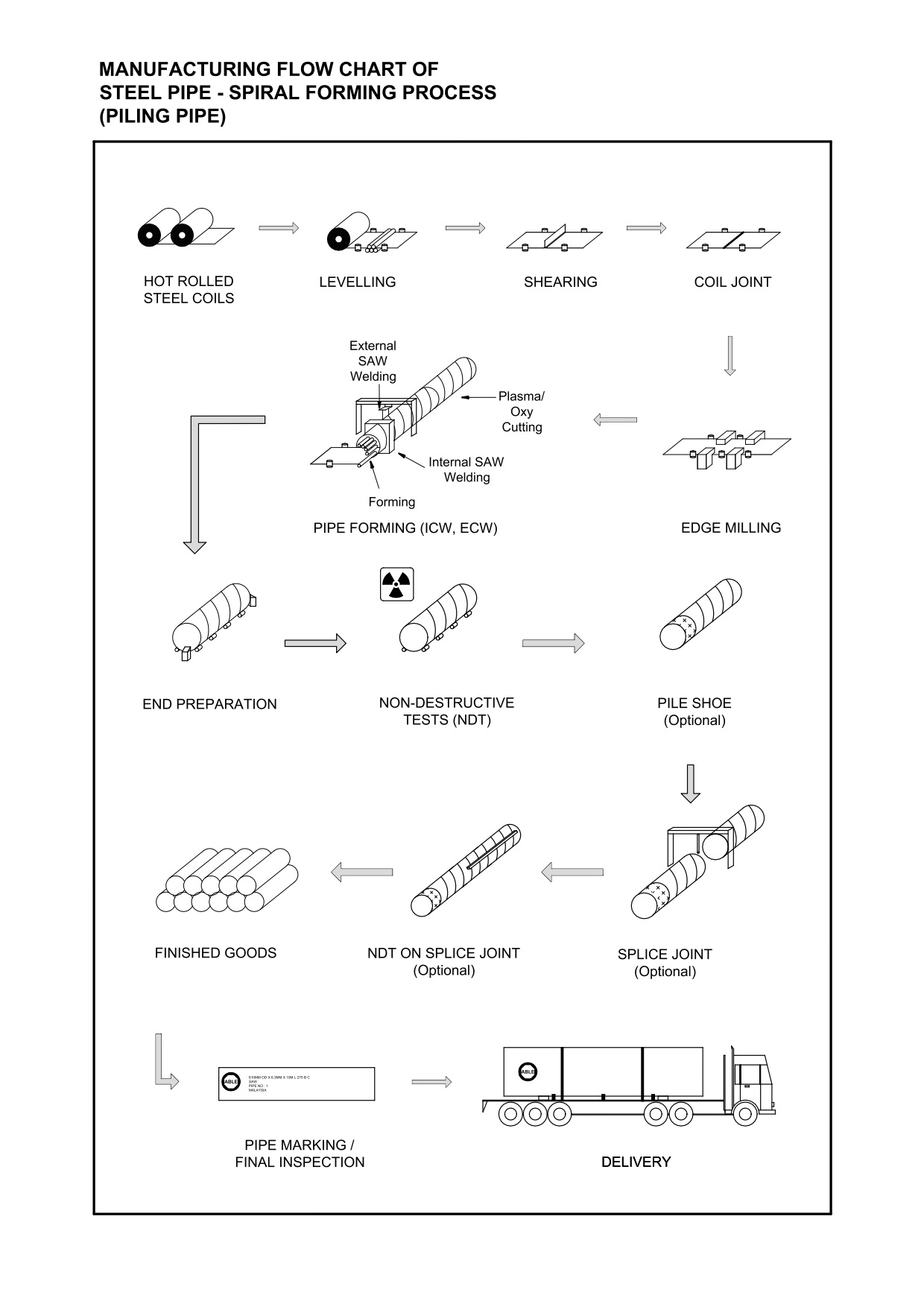

- The Spiral Forming Process (Piling Pipe)

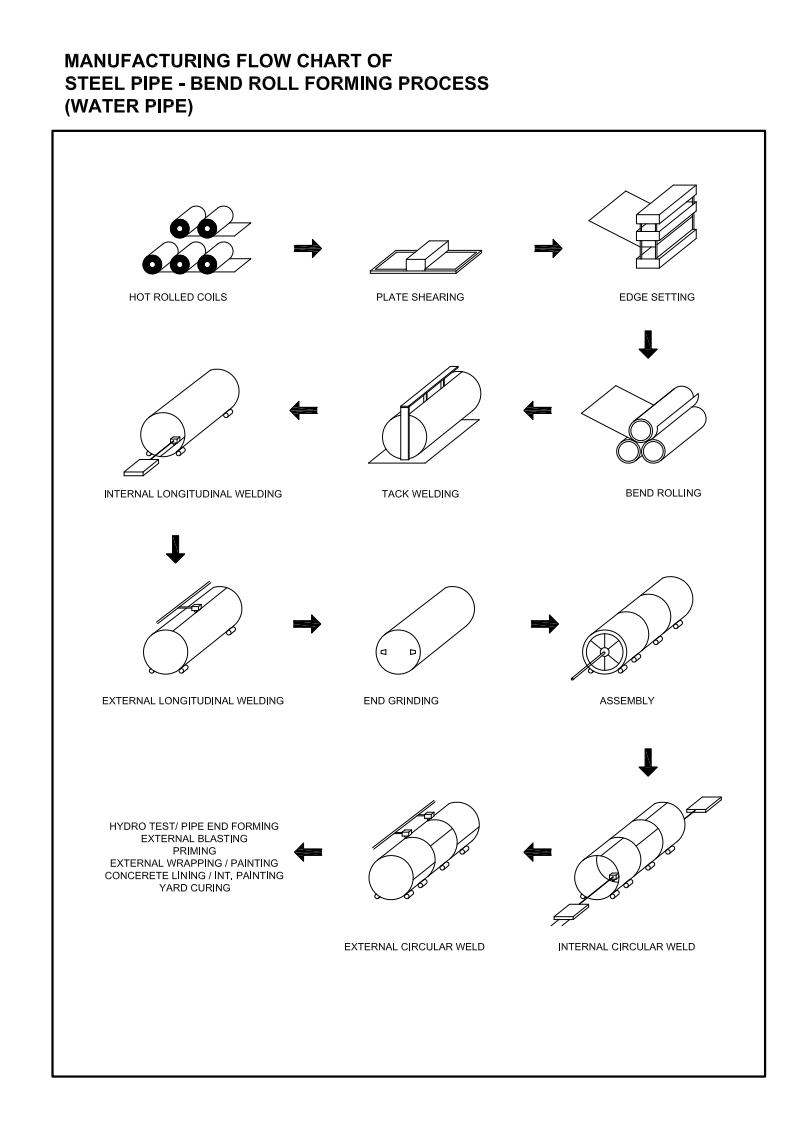

- The Bend Rolling Process

Able produces both bend roll and spiral pipes using Double Submerged Arc Welded (DSAW) welding process.

DSAW Welding Process

The pipes are welded on the inside and outside together using Double-Sided Submerged Arc Welding (DSAW) process. Depending on the thickness of the steel pipe, either both inside and outside single wire DC arc welding are used or DC and AC tandem arc welding are used in our spiral mills.

DC arc is used for the first welding pass to achieve large and concentrated penetration in welding. Followed by AC arc where better deposition rates are achieved to produce high quality finished weld.

Longer pile length of up to 30m or more are normally produced for Steel Piles used for Foundations.

Manufacturing Process

Production Range

Manufacture Process

1. Spiral Pipe Forming

2. Plasma Oxy Cutting

3.Bare Pipe

4. Hydrostatic Test/ Pipe End Forming

5.Internal Blasting

6.External Blasting

7.External Wrapping

8.Concrete Lining

9. Finished Goods